Elsner Engineering Blog

Elsner Engineering Blog

Automating Manufacturing Processes: How to Get Your Boss on Board

Do you want to integrate automation into your manufacturing process but you're unsure where to start? Maybe your biggest hurdle is selling the idea to leadership. Effectively communicating the reason why and the ROI for any major shift is necessary. We're here to help.

Do you want to integrate automation into your manufacturing process but you're unsure where to start? Maybe your biggest hurdle is selling the idea to leadership. Effectively communicating the reason why and the ROI for any major shift is necessary. We're here to help.

Consider the basic concept of Lean Manufacturing. In short, Lean is an approach designed to provide efficient and competitive production. Sounds simple in theory, right? But there is a lot involved in streamlining for efficiency. In a nutshell, the most profitable operations minimize waste and optimize their biggest resources. They drive initiatives that ensure maximum throughput and profits while ensuring their manufacturing processes are focused on quality.

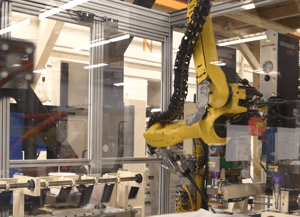

Your machinery and your people are two of your biggest costs. In a world where everyone wants it faster and cheaper, and whether you have adopted Lean methodologies or not, every manufacturer needs to keep eyes on the ultimate goal of how to deliver the highest quality product with the best, most favorable margin. We believe automation is the answer. In fact, once you've read the benefits and understand why automation is needed in your manufacturing process, you'll wonder what NOT automating will cost you.

Why Automation is a good thing:

1. The Human Factor--Save Labor, Boost Productivity: These days, labor shortages mean that it can be difficult to find the right people, and automation can mitigate those problems. In most cases, reducing the level of human participation and lessening the number of manual processes will save you. Consider the aspect of flexibility in your staffing: you can ramp up or slow down production according to demand quickly, predictably and efficiently without worrying about adding staff or extra overtime. Not only does automating reduce your labor costs, it also results in less room for human error and more consistency for greater output in the long run.

2. Improved Quality and Consistency: As we consider less human error, it means that overall, there will be a higher level of quality, precision, and accuracy. Automation makes it easier to handle repeat tasks with greater uniformity and conformity. Utilizing your employees to concentrate on more stimulating tasks can also up company morale. Generally, automated processes produce higher efficiency in production than manual operations.

3. Safer Manufacturing: Automating mundane tasks is one thing, but automating tasks that are dangerous or hazardous takes safety to the next level. Since the implementation of OSHA in the 1970's, the safety and wellbeing of workers is a front and center concern for all employers. Manufacturers benefit greatly when risky tasks are automated so that human interaction and risk is minimized.

4. Boost Productivity: Automated processes produce many productivity-related boosts. Your unit costs will go down, your throughput will go up, and you'll have more predictable and accurate throughput with far fewer defects.

5. Space-saver: Automation helps you save floorspace with a more compact footprint. You can also save space because you can more easily ebb and flow with your inventory.

All things considered, you can see why automation is needed for future growth. You don't necessarily need to reinvent the wheel when it comes to considering how to shift to automating your manufacturing. Engage an expert who has experience in customizing real-world solutions to real-world pain points. As you consider your growth plans, let us help. ELSNER has helped solve hundreds of problems over the years. And remember that if you're NOT automating, you could be costing yourself in the long run.

Contact us to discuss your custom machinery innovative solution.