Elsner Engineering Blog

Elsner Engineering Blog

Elsner Scheduled to Attend the Membrane Technology Forum in June.

Elsner will feature Filtration Automation solutions that automate spiral wound filters.

ELSNER has announced that they will be in attendance at this year's Membrane Technology Forum. They will attend the conference and exhibit alongside membrane technology leaders.

ELSNER has announced that they will be in attendance at this year's Membrane Technology Forum. They will attend the conference and exhibit alongside membrane technology leaders.

ELSNER has been building automated folding, gluing and rolling machinery for the spiral wound filter industry for nearly 20 years and are positioned as a world leader in automating processes related to manufacturing spiral wound filter elements.

“Labor pressures are nothing new, but COVID-19 has made labor-related issues even more challenging,” said Jay Roth, ELSNER’s Director of Sales. “With a lack of options and smaller staffing, continuity to maintain throughput has been difficult for many filter manufacturers. This is where automation can make all the difference. We are looking forward to sharing our solutions with those in attendance at this year's Membrane Technology Forum to help them boost efficiencies, save labor and improve quality.”

Automation offers the options needed to manage workflows even during a situation such as the coronavirus crisis. That is why despite budget shortfalls and declining productivity, many manufacturers are leaving room in the budget for investments in Automated Solutions as a long-term strategy for stability.

Coming off of record sales in the rolled wipes market during the pandemic, ELSNER has identified filtration as one of several key initiatives ELSNER is undertaking to maintain their current growth trajectory.

ELSNER will be promoting a full line of filtration machinery at Membrane Technology Forum:

Automatic Membrane Folding: The EMF-42 automatically converts membrane and plastic mesh into folded “leaves” for spiral wound elements.

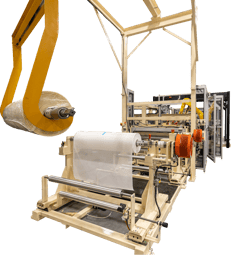

Filter Assembly and Rolling: The APB-42 provides automatic pack building. The machine is designed to bring together filter components to produce spiral wound filter elements.

Filter Assembly and Rolling: The APB-42 provides automatic pack building. The machine is designed to bring together filter components to produce spiral wound filter elements.

Filter Rolling, Taping & Gluing: The SFR-42 Automates tasks such as glue delivery & outer wrap tape application associated with the manufacture of spiral wound membrane filter elements. Our Element Rolling Table is a semi-automatic solution to filter rolling and taping.

Filter Element Finishing: The Element Trim Saw is designed to finish the edges of industrial liquid filtration elements such as those made on the ELSNER EMF-42/APB-42 Element Production Line.

Contact ELSNER for any inquiries: eew@elsnereng.com

About Membrane Technology Forum: New Membrane Technologies, Applications & Solutions

Backed by Dairy Foods magazine and American Dairy Products Institute (ADPI), the Membrane Technology Forum is the premier live event in the commercial membrane and membrane technology sector. This event covers the most important concepts and ideas, including the fundamentals of membrane technology, fouling and cleaning, and emerging new technologies and applications. Case studies will discuss real-world membrane technology challenges, outline proposed solutions, and share the final results.

The Membrane Technology Forum is the go-to source for processors, plant managers, engineers, chemists, equipment manufacturers, research and development professionals, sales & marketing specialists, technicians and many others. The program features informative technical sessions covering current topics and emerging trends. Attendees will gain fresh ideas, trusted data and proactive solutions to help their companies evolve with the changing trends in membrane technology.

About ELSNER: Founded in 1934, Elsner Engineering Works, Inc. is celebrating 85 years of family-owned, continuous operation. ELSNER is a world leader in converting equipment for a wide range of industries and offers sales and service support of its equipment from their headquarters in Hanover, Pennsylvania USA, Shanghai, China and EU support based in Germany. With over 3,000 machines in service throughout 60 countries globally, ELSNER leverages teamwork, accountability and craftsmanship to exceed customer expectations and build brand loyalty. With a 60,000 square foot expansion ELSNER is geared up for many more years of successful partnerships with their customers.