You know that time is money if you're in the manufacturing business. The faster you produce your product, the more money you'll make. That's why automation is such an essential part of manufacturing. Elsner's automated filter manufacturing machinery can help you save time and money, boost productivity, and manufacture a superior product every time. We work with various spiral wound filtration elements for various applications: desalination, food, beverage, dairy, biotech, and pharmaceutical industries. Keep reading to learn more about automation in filter manufacturing and why you should use it in your business!

5 Reasons why...

- Save on labor

These days, labor shortages mean it can be challenging to find the right people. Automating processes can mitigate those problems by reducing the level of human participation and lessening the number of manual processes. It will save you time and money, give you flexibility in staffing, and provide consistency for greater output in the long run.

- Lessen operator dependency

Automating risks means eliminating the need for workers to engage in dangerous activities or handle hazardous materials on a daily basis. By removing these elements from the equation, manufacturers can ensure that their employees have a safe working environment. An environment where they can focus on making great products instead of worrying about whether or not they'll come home safely at the end of the day.

- Enhance quality control

When considering the use of automation, it's important to remember that it will reduce human error in repetitive tasks. This will lead to higher quality, precision, and accuracy across your organization as a whole. Automation makes it easier to handle repetitive tasks with greater uniformity and conformity; utilizing your employees to concentrate on more stimulating tasks can also up company morale. Generally, automated processes produce higher efficiency in production than manual operations.

- Increase speed

Automated processes produce many productivity-related boosts. Your unit costs will go down, your output will go up, and you'll have a more predictable and accurate throughput with fewer defects.

- Provide U.S.-based support

Everyone can use a friend. Elsner offers top-notch service, parts, and training programs designed to maintain your Elsner machines' peak efficiency and productivity. With remote connectivity and skilled technicians available to travel worldwide, you can count on Elsner's renowned support to keep your operations running smoothly.

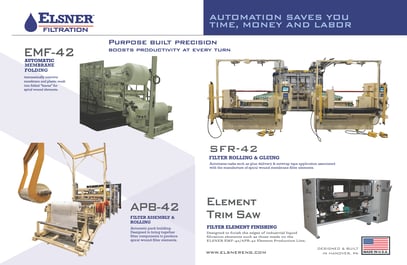

Watch the EMF-42 in action!

Contact ELSNER to discuss your filter manufacturing automation needs in reverse osmosis, microfiltration, ultrafiltration, nanofiltration, or any other automation and processing needs. RO filter assembly equipment will save you time and money.